how does a pressure regulating valve work?

Guide to Pressure Regulating Valves: Types and Applications

Pressure regulator valves are crucial components in systems that manage the flow of liquids and gases. They keep the pressure steady in a system by adjusting the flow. This makes sure everything stays safe and works well, even if the demand or supply changes.

Components of a Pressure Regulating Valve

To understand how these valves function, it’s essential to familiarize ourselves with their main components:

- Valve Body: The main structure that houses internal parts and provides the pathway for fluid or gas flow.

- Inlet and Outlet Ports: Openings through which the fluid enters and exits the valve.

- Adjusting Spring: A spring mechanism set to a specific pressure, determining the valve’s response to pressure changes.

- Diaphragm or Piston: A movable element that responds to pressure differences, controlling the valve opening.

- Seat: The surface against which the valve closes to stop flow.

- Pilot Valve (in pilot-operated types): A second valve that helps control the main valve to keep the pressure just right.

Detailed Working Principle

Pressure regulating valves work like a tug-of-war. A spring pushes one way, and water pressure pushes the other way. The valve keeps the water flow just right by balancing these two forces.

- High-Pressure Inlet: Fluid or gas enters the valve through the inlet port under high pressure.

- Spring Setting: The adjusting spring is pre-set to a desired outlet pressure.

- Diaphragm/Piston Response: The downstream pressure exerts force on the diaphragm or piston. If the pressure is too low, the spring pushes a part inside to open the valve. This lets more fluid flow through.

- Flow Adjustment: As the valve opens, more fluid flows to the downstream side, increasing the pressure.

- Balancing Act: Once the pressure reaches the set level, the forces even out, and the valve stays in place to keep the pressure steady.

- Automatic Correction: If the pressure gets too high, it pushes on a part inside the valve (like a small rubber or metal piece). This makes a spring squeeze down, which closes the valve a little. When the valve closes, less water flows through, and the pressure goes back to normal.

This constant balancing keeps the downstream pressure steady, no matter how the upstream pressure changes or how demand shifts.

Types of Pressure Regulating Valves

Pressure regulating valves come in various types, each designed for specific applications and operational requirements:

Direct-Acting Pressure Reducing Valves

- Mechanism: Utilize a spring-loaded diaphragm or piston to directly control the valve opening.

- Characteristics: Simple design, compact, and suitable for low to moderate flow rates.

- Applications: Ideal for residential water systems and small industrial applications where pressure requirements are relatively stable.

Pilot-Operated Pressure Reducing Valves

- Mechanism: Employ an external pilot valve to control the main valve, allowing for more precise pressure regulation.

- Characteristics: More complex, suitable for high-flow applications, and can handle varying pressure conditions.

- Applications: Commonly used in large-scale industrial processes, water distribution networks, and situations requiring precise pressure control.

Back-Pressure Regulators

- Mechanism: Maintain upstream pressure by releasing excess pressure downstream when a set point is exceeded.

- Characteristics: Often used to prevent pressure build-up in systems.

- Applications: Used in systems where keeping enough pressure is important, like in fuel systems and chemical processing.

Pressure Relief Valves

- Mechanism: Designed to open fully when a set pressure is exceeded, releasing excess pressure to protect the system.

- Characteristics: Serve as safety devices to prevent overpressure conditions.

- Applications: Essential in boiler systems, pressure vessels, and pipelines to prevent catastrophic failures due to overpressure.

Applications Across Industries

Pressure regulating valves are integral to numerous industries, ensuring safe and efficient operations:

Water Distribution Systems

- Function: Ensure consistent water pressure in residential, commercial, and industrial settings.

- Importance: Protects plumbing fixtures from damage caused by high pressure and ensures adequate pressure for various applications.

Gas Supply Systems

- Function: Maintain safe and consistent gas pressure in pipelines and distribution networks.

- Importance: Prevents gas leaks and ensures the efficient operation of gas-powered equipment.

Industrial Machinery

- Function: Protect equipment from pressure fluctuations that could affect performance or cause damage.

- Importance: Ensures machinery operates within specified pressure ranges, enhancing longevity and reliability.

Fire Protection Systems

- Function: Regulate water pressure in fire suppression systems to ensure optimal performance.

- Importance: Ensures that sprinklers and hoses deliver water at pressures suitable for effective firefighting without damaging equipment.

HVAC Systems

- Function: Control refrigerant and water pressures within heating, ventilation, and air conditioning systems.

- Importance: Maintains system efficiency and prevents damage to components caused by pressure variations.

Oil and Gas Industry

- Function: Manage pressures in extraction, refining, and distribution processes.

- Importance: Ensures safety and efficiency in handling volatile substances under high pressures.

Benefits of Using Pressure Regulating Valves

Implementing pressure regulating valves in a system offers several advantages:

- Safety: Prevents overpressure conditions that could lead to equipment failure or hazards.

- Efficiency: Maintains optimal operating conditions for machinery and processes, ensuring consistent performance.

- Cost Savings: Reduces wear and tear on equipment, leading to lower maintenance costs and extended equipment lifespan.

- System Protection: Shields sensitive components from pressure spikes that could cause damage.

- Energy Conservation: Maintaining appropriate pressure levels optimizes energy consumption, leading to potential energy savings.

Maintenance Practices

Regular maintenance of pressure regulating valves is crucial to ensure their proper functioning and longevity. Key maintenance practices include:

- Regular Inspections: Periodically check the valves for signs of wear, corrosion, or damage. Look for leaks, unusual noises, or vibrations that could indicate issues.

- Cleaning: Remove any debris or buildup that could impede valve operation. Ensure that all moving parts are free from obstructions.

- Testing: Verify that the valve maintains the correct pressure settings and responds appropriately to pressure changes. Conduct functional tests to ensure proper operation.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. Ensure that the lubricants used are compatible with the system’s media.

- Replacement of Worn Parts: Replace seals, springs, or other components that show signs of wear or fatigue. Use manufacturer-recommended parts to maintain valve integrity.

By following these simple maintenance steps, your pressure regulating valves will work well and last longer.

Selection Criteria

Choosing the right pressure regulating valve for a specific application involves considering several factors:

- Pressure Requirements: Determine the maximum and minimum pressure levels the valve needs to regulate.

We are industry leaders.

P.A. Spa makes special valves that help control water pressure in different machines. These high-pressure regulator valves keep the pressure at the right level, so everything works smoothly. Here’s an easy-to-understand overview of some key models:

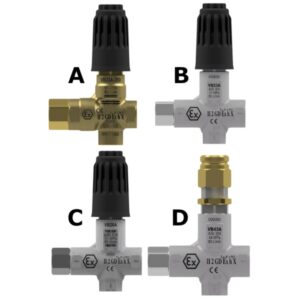

1. VRP 175

- Purpose: This valve maintains steady pressure in various systems.

- Usage: Car washes and city cleaning machines commonly use it.

2. VRP 200

- Purpose: Designed for systems that need a pressure of up to 200 bar.

- Usage: Ideal for setups requiring this specific pressure level.

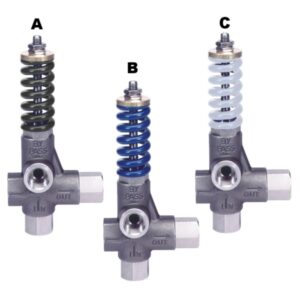

3. VRP 23, VRP 43 – AISI 303

- Material: Made from AISI 303 stainless steel, this material offers high strength and corrosion resistance.

- Benefit: These valves last longer and work well in tough conditions.

4. VRP 26 – AISI 316 with Viton O-Rings

- Material: Built with AISI 316 stainless steel and Viton O-Rings for extra durability.

- Benefit: Suitable for challenging environments because of its sturdy construction.

5. VRP 280

- Purpose: Suitable for systems that need a pressure of up to 280 bar.

- Usage: Used in applications requiring this higher-pressure level.

6. VRP 350

- Purpose: This valve handles pressure levels of up to 350 bar.

- Usage: Designed to meet demanding high-pressure requirements.

7. VRP 450-200

- Purpose: Made for systems with high flow rates and a pressure of up to 200 bar.

- Usage: Perfect for applications where a lot of fluid moves through at this pressure.

8. VRP 450-300

- Purpose: Suitable for high-flow systems requiring a pressure of up to 300 bar.

- Usage: This system handles large fluid volumes at this pressure.

9. VRP 600

- Purpose: A strong valve designed for high-pressure systems.

- Usage: Ideal for applications that need extremely high-pressure control.

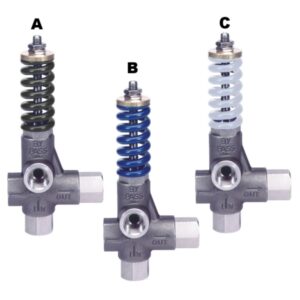

10. Pulsar Zero with Knob and Micro-Switch

- Easy Adjustment: Comes with a knob to set the pressure easily.

- Safety: Includes a micro-switch for better control and safety.

- Benefit: When not in use, it reduces the pressure to zero to protect the system.

11. Pulsar RV – Bypass Valve with Knob

- Adjustable Pressure: Allows users to set the desired pressure.

- Bypass Function: Manages extra pressure to keep the system safe.

- Benefit: Helps maintain safe pressure levels by redirecting excess flow.

12. VB 350 S

- Purpose: A durable valve designed for high-pressure applications.

- Benefit: Ensures reliable performance in demanding situations.

13. VB 350 Unloader Valve with Knob

- Features: It features a knob for precise pressure adjustment.

- Benefit: Allows users to control pressure levels effortlessly.

14. VB 350 with Knob and Microswitch

- Features: Combines a pressure-setting knob with a microswitch for added safety.

- Benefit: Provides enhanced control and protection for the system.

15. VB 36

- Purpose: A versatile valve suitable for various high-pressure applications.

- Benefit: Offers reliability and ease of use across different setups.

16. VB 43 – AISI 303

- Material: Made from AISI 303 stainless steel for excellent rust resistance.

- Benefit: Ideal for tough environments because of its durable construction.

17. VB 80/150 – 280 – 400 – AISI 303

- Features: A series of valves with different pressure ratings, all made from AISI 303 stainless steel.

- Benefit: Provides durable options for various pressure needs.

18. VB 80/150 – 280 – 400 – AISI 303 with Viton O-Rings

- Features: Similar to the previous series but includes Viton O-Rings for better chemical resistance.

- Benefit: Offers enhanced durability in chemically challenging environments.

19. VB 80/280 – 400 – Norsok – Unloader Valve Duplex SST with Viton O-Rings

- Standards: Meets Norsok standards and is made from duplex stainless steel with Viton O-Rings.

- Benefit: Designed for superior performance in harsh conditions.

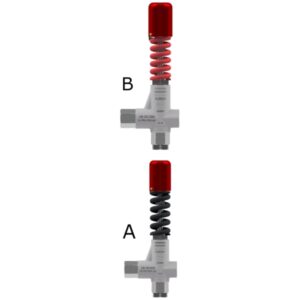

20. VB23A – VB26A – VB33A – VB43A – Valve Bypass ATEX

- Certification: Certified for use in explosive atmospheres (ATEX).

- Benefit: Ensures safety in hazardous environments.

21. VB36-HT 39MPa – Unloader Valve for Hot Temperature Water

- Purpose: Built to handle hot water applications up to 39 MPa.

- Benefit: Provides reliable performance under high-temperature conditions.

The design of each valve ensures optimal performance.

Leading Suppliers of Pressure Regulator Valves in the UAE

AL MOUJ AL ABYADH: Leading Pressure Regulator Dealer in the Middle East

AL MOUJ AL ABYADH sells pressure regulator valve and industrial tools in the Middle East. Their dedication to quality and customer satisfaction has earned them a strong reputation in the region.

Why Choose AL MOUJ AL ABYADH?

Several factors make AL MOUJ AL ABYADH a preferred choice for pressure regulators:

- Quality Products: They offer reliable and durable products suitable for various industrial applications.

- Customer Support: Their knowledgeable team provides guidance to help customers select the right products for their needs.

- Timely Delivery: Efficient logistics ensure that products reach customers promptly.

Other Notable Pressure Regulator Suppliers in the Middle East

While AL MOUJ AL ABYADH is a leading supplier, there are other notable companies in the region:

Middle East Valve

Middle East Valve, based in the UAE, sells different types of pressure regulator valves. These include direct-acting and pilot-operated valves. They serve industries such as oil and gas, power generation, and water treatment.

Weldtron

Located in Dubai, Weldtron is an authorized dealer of gas regulators from leading manufacturers, including HARRIS. They provide quality gas regulation solutions for various applications.

Hashtron

Hashtron supplies top-quality pressure regulators and gauge valves in Dubai. They are a trusted distributor for reliable industrial solutions.

Al Muftah International Trading

Operating in Sharjah, Al Muftah International Trading specializes in pressure regulators, gas distribution, and liquid nitrogen containers. People recognize them for their diverse product range and excellent customer service.

Conclusion

AL MOUJ AL ABYADH is a top seller of pressure regulator valve in the Middle East. They have many high-quality products and provide great customer service. Other notable suppliers in the region also provide reliable solutions to meet various industrial needs.