Powerful high pressure plunger pumps

Powerful High-Pressure Plunger Pumps

High-pressure plunger pumps are powerful machines designed to move fluids at extremely high pressures. Unlike standard pumps, they use a plunger mechanism, enabling higher pressure and improved flow control. This makes them ideal for demanding industrial applications where reliable and strong fluid force is essential.

The exceptional performance and durability of high-pressure pumps distinguish them in the industry. Built with robust materials, these pressure pumps withstand harsh environments and consistently deliver power, even with extended use. Additionally, their unique construction ensures they can handle fluids with varying viscosities, making them versatile for different tasks.

High-pressure pumps are vital in many industries. For instance, in cleaning, they generate the force needed for effective power washing, removing tough dirt and grime. In mining, they help move slurry and other heavy materials. Moreover, in the oil and gas industry, they are crucial for precise and powerful fluid control.

This blog will explore the efficiency and “power” of high-pressure pumps. This guide also examines how these reliable machines drive efficiency across industries, simplifying and accelerating challenging tasks.

How High-Pressure Pumps Work

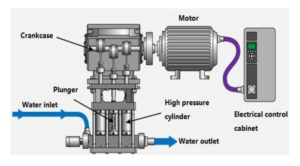

High-pressure pumps, specifically plunger pumps, work through a straightforward yet powerful mechanism. They use a plunger, pistons, and valves to generate high pressure. Here’s how it all comes together:

At the heart of a high-pressure pump, the plunger or piston moves back and forth inside a cylinder. When the plunger moves back, it creates a low-pressure area that pulls in fluid through an inlet valve. As the fluid moves forward, it exits through an outlet valve. This back-and-forth motion creates a continuous flow of pressurized fluid.

The key components—plungers, pistons, and valves—each have a role in achieving high-pressure power. For example, the plunger, made from durable materials, handles high pressures without wearing down quickly. The pistons drive the plunger’s motion, while the valves control fluid flow, ensuring that only high-pressure fluid exits the pump.

This process converts the pump’s mechanical energy into a powerful fluid force, enabling industrial cleaning, mining, and oil extraction. Consequently, the power of high-pressure pumps makes them invaluable for tough materials and intense cleaning tasks.

Diagrams of a high-pressure pump’s structure help visualize component interactions, clarifying the mechanics behind their performance.

Key Benefits of Using High-Pressure Plunger Pumps

Efficiency: These high-pressure pumps deliver powerful performance while using energy efficiently. Designed to operate at various pressures, they handle both light and demanding tasks efficiently. Consequently, this efficiency translates into energy savings, especially in continuous operations.

Durability: High-pressure pumps feature rugged materials, allowing them to withstand long-term, heavy-duty use. They can endure harsh conditions and high workloads without frequent breakdowns. This durability makes them reliable tools in industries like mining and oil & gas, where equipment must withstand tough environments.

Versatility: High-pressure pumps are versatile and find applications in multiple sectors. From car wash stations to industrial cleaning and even in agriculture, these pumps adapt to diverse needs. Their ability to handle various fluid types and pressures makes them suitable for both small and large-scale applications.

Cost-Effectiveness: Combining efficiency and durability, these pressure pumps provide a cost-effective solution for businesses. With their robust construction, they require fewer repairs and replacements. Thus, energy savings and minimal downtime reduce operational costs, making high-pressure pumps a smart long-term investment.

Popular Applications of High-Pressure Pumps

High-pressure plunger pumps are essential tools in various industries, valued for their powerful performance and versatility. Here are some popular applications where these pressure pumps excel:

Industrial Cleaning: High-pressure pumps are widely used in industries to remove tough residues from machinery, equipment, and surfaces. For example, they effectively clear away oil, grime, and stubborn contaminants from factory floors and production lines. The intense force of a high-pressure pump removes tough residues, reducing manual labor and boosting cleaning speed.

Agricultural Applications: In agriculture, high-pressure pumps play a critical role in high-efficiency irrigation systems. They are ideal for delivering water over long distances or large crop fields, ensuring every section receives sufficient water. jet washer pumps efficiently power center-pivot irrigation in large fields, supporting crop health and yield.

Oil and Gas: High-pressure pumps are crucial for maintaining pipelines and cleaning equipment in the oil and gas sector. They help remove blockages and residues within pipelines, preventing disruptions in the flow of oil and gas. Additionally, they clean drilling rigs and machinery, which is essential for safe and efficient operations. A high-pressure pump in this sector improves productivity by reducing downtime and ensuring safe, clean equipment.

Construction and Mining: In construction, high-pressure pumps are used for cleaning concrete forms, tools, and machinery. In mining, they are crucial for dust suppression, a necessary process to improve air quality and safety. For instance, jet washer pumps spray water on dusty mine surfaces, reducing dust and protecting workers from respiratory issues.

Each of these applications demonstrates how high-pressure pumps increase productivity by reducing manual labor, enhancing cleaning efficiency, and maintaining operational safety across industries.

Choosing the Right Washer Pump

Selecting the right high-pressure pump requires matching your application’s demands to the pump’s specifications. Here are key factors to consider:

Pressure Requirements: The pump’s PSI (pounds per square inch) must meet the job’s pressure needs. For heavy-duty cleaning, a high-pressure pump with a higher PSI is essential, while lighter tasks may require less. Matching PSI ensures efficient cleaning without damaging surfaces.

Flow Rate: The pump’s flow rate, measured in gallons per minute (GPM), directly impacts cleaning power. Higher GPM means faster water output, ideal for covering large areas quickly. Lower GPM, however, allows for more precise cleaning. For example, industrial cleaning may require high GPM, whereas smaller applications may not.

Material Compatibility: The pump’s materials should be durable and corrosion-resistant, especially for handling harsh chemicals or saltwater. Manufacturers commonly use stainless steel and other wear-resistant materials in high-pressure pumps. In oil and gas applications with corrosive materials, durable materials ensure longer pump life with minimal maintenance.

Temperature Tolerance: Some applications require hot water, while others need cold. Choosing a washer pump that tolerates the temperature requirements of your task is critical. For instance, high-temperature pumps aid grease removal by using hot water to break down oils more effectively.

Pump Sizing: The size of the pump depends on the scope of your application. For example, large industrial cleaning needs a pump with high PSI and GPM, while smaller tasks may need lower values. Therefore, consult pump sizing guides or manufacturers to balance pressure and flow rate for your application.

Choosing the right high-pressure pump boosts performance, productivity, and lifespan, making it a cost-effective choice.

| Model | Max Pressure | Flow Rate | RPM | Power (kW) | Shaft Type | Max Temperature | Weight (kg) | Inlet Size | Outlet Size | Country of Origin |

|---|---|---|---|---|---|---|---|---|---|---|

| PX1735IL | 350 bar | 17 l/min | 1450 | 11.2 | 24 mm Male | 65°C | 19.6 | 1/2” | 3/8” | Italy |

| PX2150IR | 500 bar | 21 l/min | 1450 | 20.3 | 24 mm Male | 65°C | 19.6 | 1/2″ | 3/8” | Italy |

| GXX2410R | 1000 bar | 23.8 l/min | 1450 | 44.9 | 40 mm Male | 45°C | 78 | 1” | 24×1.5 | Italy |

| NPM1425GR | 250 bar | 14.5 l/min | 3400 | 6.8 | 1″ Female | 65°C | 10.7 | 1/2″ | 3/8” | Italy |

| NHDP1120G1L | 200 bar | 11.4 l/min | 3400 | 4.4 | 1″ Female | 65°C | 8.9 | 1/2” | 3/8” | Italy |

| GXT1515SL | 150 bar | 150 l/min | 1450 | 43.4 | 40 mm Male | 65°C | 67.5 | 1 1/2” | 1” | Italy |

| MXT1015R | 150 bar | 100 l/min | 1450 | 27.7 | 30 mm Male | 65°C | 32.5 | 1 1/4” | 3/4” | Italy |

| NMT1520ESL | 200 bar | 15 l/min | 1450 | 5.7 | 24 mm Male | 65°C | 11.8 | 1/2” | 3/8” | Italy |

| XXT7015IR | 150 bar | 70 l/min | 1450 | 20.0 | 24 mm Male | 65°C | 18.4 | 1” | 3/4” | Italy |

| XLT2520HTIL | 200 bar | 25 l/min | 1450 | 9.6 | 24 mm Male | 85°C | 17.8 | 3/4” | 1/2” | Italy |

Maintaining Pressure Pumps for Longevity

Maintaining a high-pressure pump properly is essential for extending its life and keeping it running efficiently. Here are some effective maintenance tips:

Regular Inspection: Routine checks help identify any wear and tear early on. Look for leaks, unusual sounds, or changes in performance. Regular inspection addresses any issues before they become serious.

Replacing Parts: High-pressure pumps have components, like seals and valves, that naturally wear down over time. Replacing these parts as needed helps maintain pressure levels and prevents more extensive damage. Seals, in particular, keep the pump working efficiently by preventing leaks.

Using Correct Lubricants and Fluids: Proper lubrication is essential for reducing friction in the pump’s moving parts. Always use the recommended lubricants and fluids to avoid unnecessary wear. The right lubricant ensures that parts stay cool and reduces the risk of damage.

Preventative Maintenance: Preventative care is key to reducing downtime and repair costs. By performing regular maintenance, you minimize unexpected breakdowns, which can disrupt operations and increase expenses.

Following these practices will help your high-pressure pump perform reliably, saving both time and money in the long run.

Latest Innovations and Technologies in washer Pumps

High-pressure pumps have seen significant innovations in recent years to meet evolving industrial needs.

Smart Technology: Many high-pressure pumps now come with IoT-enabled monitoring. This technology allows real-time tracking of pump performance, enabling early detection of issues. It reduces downtime and helps optimize maintenance schedules, saving time and costs.

Eco-Friendly Designs: With a focus on sustainability, manufacturers are developing energy-efficient pressure pumps that reduce power consumption. Eco-friendly models lower costs and reduce environmental impact, ideal for industries aiming to cut emissions.

Enhanced Materials: Advanced materials, like specialized alloys and high-grade stainless steel, improve durability and heat resistance. Manufacturers design these materials to withstand high pressures and extreme temperatures, extending the pump’s life and ensuring reliable performance.

These innovations allow high-pressure pumps to meet demands, providing smarter, greener, and more durable options.

Conclusion and Call to Action

In conclusion, washer pumps are versatile, durable, and essential, providing powerful solutions for cleaning, irrigation, and maintenance. When selecting a high-quality pump, a trusted brand like HAWK INTERNATIONAL ensures lasting performance and efficiency.

If you are ready to experience a top-tier washer pump, explore our offerings. Explore our products or contact us for a consultation. Our team is here to help you find the right pump tailored to your needs, boosting productivity while reducing costs. Begin your journey by visiting our product page today.